Rapid prototyping rp techniques in the sheet metal forming industry is developed to quickly test the form and fit of new sheet metal products on a prototype basis as well as for production runs characterized by small lot sizes.

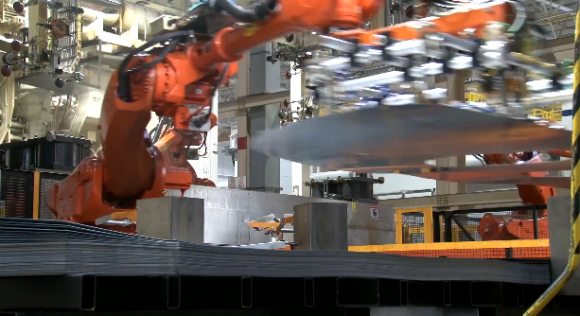

Ford sheet metal rapid prototyping.

We do not crowd source your components.

We fabricate finish and deliver your parts from our facility in west bend wisconsin.

Ford calls this ford freeform fabrication technology f3t.

Rapid prototyping for sheet metal parts posted in the technical forum.

Rapid prototyping is a decades long trend in manufacturing but it s gotten special attention.

Automotive applications include prototyping concept vehicles and vehicle personalization.

Can do sheet metal stampings in hours instead of weeks.

Posted on july 9 2013 by mcg.

Rapid prototyping for sheet metal components.

To speed up prototyping ford has created a rapid process they call the ford freeform fabrication technology f3t for short.

This article provides an overview of some of the technologies used for rp and low volume production of sheet metal.

Here s some interesting new technology that has huge potential all across the automotive specialty industry.

Ford has introduced a sheet metal process that eliminates the need for expensive dies.

By john hewitt on july 4 2013 at 10 25 am.

Ford reveals new rapid prototyping and low volume production techniques w video.

See how ford does it with this short video video.

Over the last 100 years or so the ford motor company has gotten really good at stamping sheet metal parts.

Boomerang provides quick turnarounds of rapid prototypes sheet metal fabrication as well as low volume production short run assemblies and custom one of a kind products for your next trade show event.

Sadly stamping can take up to 6 8 weeks from the time the design leaves the cad station so it s not great for prototyping.

Ford unveils rapid prototyping for sheet metal parts.

Once fully developed the ford freeform fabrication technology f3t will allow for lower costs and ultrafast delivery times for prototypes that require sheet metal parts up to three business days versus two to six months needed with conventional methods.

Ford engineers are developing a highly flexible first of its kind patented technology to rapidly form sheet metal parts for low volume production applicati.

/cdn.vox-cdn.com/assets/2894405/Screen_Shot_2013-07-09_at_7.59.28_AM.png)